Punching Machine Making Holes for Angle Steel CNC Angle Line

Basic Info.

| Model NO. | JGX2020/JGX2020S |

| Controlling Mode | CNC |

| Automatic Grade | Automatic |

| Power Source | Hydraulic Pressure |

| Precision | High Precision |

| Certification | GS, CE, RoHS, ISO 9001 |

| Condition | New |

| Max. Length of Blank(M) | 13 |

| Shearing Mode | Single Blade Strengthen Type |

| Punching Force (Kn) | 1800 |

| Transport Package | Standard Shipping |

| Trademark | Raintech |

| Origin | China |

| Production Capacity | 200e/Year |

Product Description

Punching Machine Making Holes for Angle Steel CNC Angle Line

Product Description

This machine is mainly used for punching holes and cut to length on angle steel. The positioning, feeding of the machine are all driven by servo motors,mainly used in Telecommunication tower, solar mounting, warehousing storage, granary, scaffolding and automobile industries.

The main advantage of this machine as follow:

- The machine adopts our own self-developed Taurus software can be used when the device is turned on, and stopped when it is turned off, and it does not need to return to the original point when it is restarted. It can achieve continuous work ,greatly improve the working efficiency.

- On the basis of supporting dxf, the machine supports TEKKELA NCformat to meet the various production needs of customers

- The probe sensor of the entire production line is reduced by 1 time, which reduces the failure rate of the whole machine by 1 time, which greatly decreases the maintenance and use costs.

- It can finish punching, marking and cutting functions automatically on one machine.

Product Parameters

Technical Specification:| Model | Specifications | JGX2020 | JGX2020S | |

| Processing Area | Minimum Angle size(mm) | 63*63*4 | ||

| Maximum Angle size(mm) | 200*200*20 | |||

| Maximum Angle Length(m) | 12/14 | |||

| Punching | Punching Force(KN) | 1500 | ||

| Number of Punches per Side | 3 | |||

| Max. Punching Hole Size(mm) | 26 | |||

| Adjustment Range(mm) | 20-180 | |||

| Type Ability | Marking Force(KN) | 1200 | ||

| Group of Marking Characters | 4 | |||

| Qty of Marking Characters | 12 | |||

| Character Size(mm) | 14*10*9 | |||

| Shear | Shear Nominal Force(KN) | 2000 | 4300 | |

| Shear Mode | Double blade | Single Blade | ||

| CNC axis Number | 3 | |||

| Feeding Speed(m/min) | 40-80 | |||

| Feeding Mode | Servo In Feeding | |||

| Processing Accuracy | Reunite with GB2694-2010 | |||

| Programming Mode | Automatic conversion of lofting software or CAD drawing | |||

| Program Function | Real-time monitoring, fault display, fault alarm, etc. | |||

| Weight(Ton) | 13Ton | 14Ton | ||

| Power(KW) | 35kw | |||

| Dimension(m) | 28x2.2x4(LxWxH) | |||

Main Component

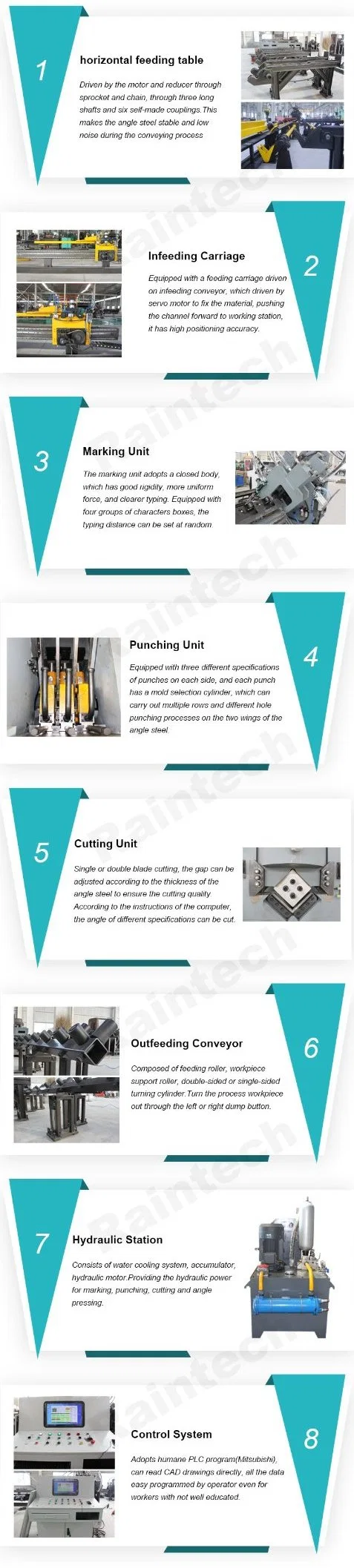

The main working process as follows:

- The angle steel will be loaded on the transverse table is moved by the chains,then the loading system load the angle material on the infeed conveyor

- The angle steel clamped and positioned by PLC controlled gripper arm, then will be brought into the marking unit first

- After materials are positioned,

- Hydraulic clamps fall and hold materials.

- The Marking unit has 4 groups of Character Boxes, it will mark according to the program automatically.

- There are three punching heads on both left and right side, the diameter of punching head can be different or the same, punching head can move up and down according to the program value.

- After the hole is proceed, upper hydraulic clamps are opened and the materials is positioned to the next punching coordinates again. All these operations are repeated for the whole length of the materials.

- After punching, the work piece can be cut to lenth by Cutting Unit, and unload by discharge conveyors automatically.

Feature

1. Adopts servo motor feeding system with high efficiency and steady high precision2. The key parts of electrical, hydraulic and pneumatic are international famous brand to assure the high and steady quality3.The key cable (rotary coder cable,PLC cable etc.)imported from Germany , will not cause the accuracy error because of the signal interference.4.Simple programme,easy operation, the user only need to input the parts size, hole diameter, stadia , parts number. Or can transform from CAD/CAM5.The computer display by many language for easy operation, can display the parts drawing6.Fully automatic process of marking, punching and shearing7.Have the self-diagnostic function8.Four shear functions, can be chosen freely(shear the front, back, both side shear, free of shear),can make sizing material9.The machine equipped with retainer and pressing devices, suitable for the angle steel with bigger bending. Our company have made completely improvement on the front and back retainer device to make sure the new structure avoid the spring can't be sprang after using sometime, which ofen happens in other companies

Packaging & Shipping

1 Lifting the machine into container2 Disassemble and pack with film for anti-humidity3 Machine trial before dispatch4 Loading the packages to container5 Fix with steel wire ropes in container to avoid damage6 Close and sealthe container7 Transport container to the port8 Ships and our machines go to the destination port

Company Profile

Jinan Raintech Machinery Industry Co., Ltd is a high-tech enterprise that integrates product development, designing, production, sales and service in metal roll forming and coils processing industry.Our Products :including various kind of metal profile roll forming machines, such as solar strut panel roll forming machine, automobile bumper roll forming machine, green house structure roll forming machine, truck beam roll forming machine, highway crash barrier roll forming machine, etc. Tube mills and coils slitting line, cut to length lineOur History: Our factory established in 2008 by one of our company founder Mr. Xu, who was as leader of china roll forming technology research team in SINOMRCH more than 10 years. Since 2008, we started design , engineering and manufacturing of all kinds of roll forming lines, including many difficult lines at same level of world advance technology. At the same time, we also design and produce cut to length line, slitting line and tube mills on the high level quality in china.Our Technical Strength : We have advance and earliest technology on metal forming and processing . Since 2008, have been succeed in many difficult lines which require high precision, high speed, and big strength used in railway, highway, metro system, electrode plate,solar structure , automobile etc. We have our special design on machine structure and rollers design, punching and cutting design to assure the speed , accuracy and life of machine. We are coincidental for bigger challenge in future on keep advanced in this fieldOur Team : We own an professional oversea marketing team leads by our CEO Ms. RainMain technical support team lead by Mr.Xu and after-sales service team with engineers.We also have local service team in some countries all over the worldOur Service : We provide complete process on quality control, machine trial , TUV, SGS BV inspection before dispatch. And provide free installation and training at customer site. And moreover, we have our own professional local service team in some countries such as India, Egypt , Italy etc.Our Goal : we have been devoted to the more advance technology in metal roll forming and processing field , trying our best to be the first level of roll forming technology in the world famous manufacture list

FAQ

- What's your advantage ?

A: We assure each machine dispatched from our factory a long-life usage with easy operation and humane design.We consider help our customer to hence the production efficiency and save your human power as our aim.2. How l believe you?

A: Welcome to visit us to check our plant and ability, the payment method can be chosen and the third party inspection through Alibaba is available.3. What about the warranty of your products?

A: We provide 12 months warranty since the machine arrived at customer site , free charge of spare parts and oline maintenance service4. Where are you? Can l visit you?

A: our factory located in Shandong province, china, welcome to visit us at any time.5. How about the delivery time?

A: For standard model, the delivery usually 25 days since the advance payment receipt. For the customized products, the delivery time will follow our agreement with customer.We never receive any complain from our customers for the delivery time6. What kind of payment does your company support?

A: TT,100% LIC at sight,Cash, Western Union are accepted. If you have other payment terms, welcome discuss with us.