Category

Kj1625 Serrated Blades for CNC Oscillating Knife Cutting Machine for Cutting Car Mats

kj1625 serrated blades for cnc oscillating knife cutting machine for cutting car mats Model No.: KJ-1625 Work plate size

Basic Info.

| Model NO. | KJ1625/1615/1630 |

| Power Source | Electric |

| Layout | Horizontal |

| Cutting Speed | 1500mm/S |

| Safety Device | Infrared Radiation/Anti-Collision/Emergency Stop |

| Cutting Thickness | 50mm |

| Power | 9-11kw |

| Voltage | 110/220/380V |

| Transport Package | Wooden Box |

| Specification | 1600*2500mm |

| Trademark | kangjia |

| Origin | Jinan China |

| HS Code | 8461500090 |

| Production Capacity | 100 Unit / Month |

Product Description

kj1625 serrated blades for cnc oscillating knife cutting machine for cutting car mats

Model No.: KJ-1625

Work plate size: 2500 mm * 1600 mm

Cutting speed: Max. 140 m / min.

Cutting thickness: 0.1 mm ~ 50 mm

Cutting accuracy: ±0.1mm

Material fixed type: Vac-sorb

Working voltage: 110V / 220V / 380V/±10% 50hz / 60hz

kj1625 serrated blades for cnc oscillating knife cutting machine for cutting car mats

Applicable cutting materials: different kinds of soft materials, such as car mats, car seat, PVC, embroidery accessories, foam composite material, XPE, coiled mats, leather, silicone, rubber, truck tarpaulin, cardboard, plastic board, Grey board, white board, gasket,etcApplication: widely used in automotive interior industry, garment, shoe, bag, packaging industry and advertising industry.Functions: cutting(oscillating cutting tool)Optional cutting tool: the cutting tool is optional according to customer's requirements, such as rotary cutting tool, punching, v-cutting tool, creasing wheel,milling cutting tool.Features: Oscillating knife cutting, fast speed, high efficiency; saving material and labor, more convenient and easier to operate for user.

Technical Data

| Model | KJPD-1625 (belt transmission) |

| Operating Characteristic | Computer operation is carried out simultaneously with the cutting machie, quickly complete the data transmasion, and can be used continusly. |

| Overall dimension | 3260*2120*1315mm |

| Working area | 2500mm * 1600mm |

| Cutting speed | <=140m/min (per material) |

| Cutting thickness | 0.1-50mm |

| Cutting accuracy | ±0.1mm |

| Cutting material | Flexible materila, such as leather, coiled mat, sponge, foot mat, cardboard, sofa, cloth, PE board etc. |

| Multifunctional head for different cutter | Half knife, full knife, punching roller, V-cutter, milling knife, pneumatic knife, eletric knife, Circular knife (round knife / rotary knife); pin |

| Material fixed type | Vac-sorb (vacuum absorption) |

| Location mode | Infrared laser lamp |

| Drive motor | Delta, Panasonic, YASKAWA, Fuji can be selected. |

| Power of suction fan | 9kw |

| Working voltage | 220V/380V/±10% 50hz/60hz |

| Safty device | Mechanical anti-collision device or FWD DS or scram button |

| Transmission interfacr coffret | Enternet transmission |

| Driving method | belt |

| Control system | LED touch screem |

| Guid rail | Brand: Yintai |

| Frame structure | Body welding |

| Suction case | Aluminum case |

| Compatible software | Kangjia intelligent software |

| Driving system | Servo motor |

| Cetificate | CE/SGS; ISO9001/ISO14001/ISO18001 |

Product advantage:

Application:

Application of vibrating knife cutting machine

Osciliting knife cutting machine can cut can cut fabric, leather, cardboard, plastic, paper, rubber, EVA foam, and it can cut many types of foam, such as closed cell foam, rubber foam, foamex, foam core, KT board, EPE foam, polyethylene foam, PE foam, PVC foam, etc. It's widely used for packaging protection, advertising display, termal insulation, model & mock up making, puzzle and pattern cutting, etc.

Advantages of oscillating knife cutter :

1. Knife cutting technology, non-laser cutting, no scorching, discoloration, no odor, and flat cut.

2. CNC cutting replaces the traditional manual development design and proofing, shortening the corresponding development time.

3. Quickly shaped cutting without the need of a die to meet the customer's production goals of small batches and multiple styles, creating a standardized and practical complete solution.

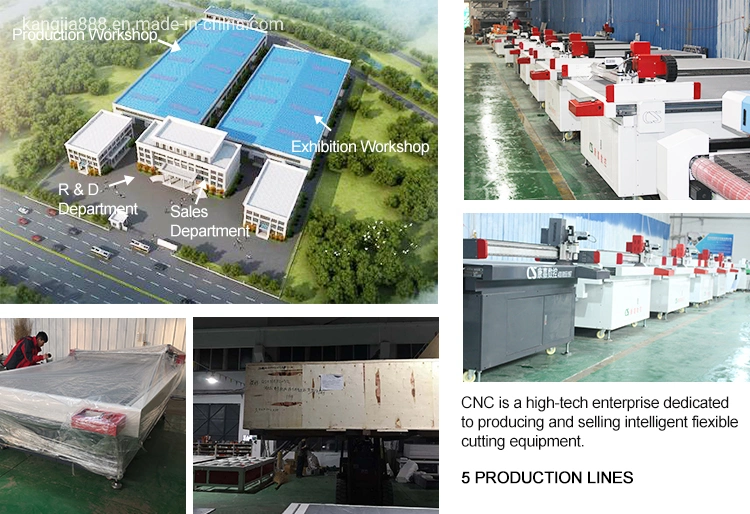

Packaging & Shipping:

Packing details:

The normal package is wooden box(Size: L*W*H). If export to european countries, the wooden box will be fumigated. If container is too tigher, we will use pe film for packing or pack it according to customers special request.

Company workshop:

Our Team:

Training Room for customers:

Certification:

Why Choose Us

1. Saving labour and material cost2. Saving time3. Everyone can operate and cut without lots of skills4. Boost production capacity5. Consistent accuracy even with complicated patterns6. Reduces your lead times of pattern cutting from your clients7. Wide range of clothes/garment/apparel material application8. Running in a high automaton9. Special design: less moving structure guarantee low down time and easy in installation and maintain10. Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts. 11.Good experienced engineers12. CNC control13. Knife cutting method: oscillating Blade with multifunctional tool heads14. Easy conversion15. With more and more agents / partner joining us, after sales team can be in your country by your side.