Category

Price 4 Lines HDPE, LDPE Plastic Nylon Flat Garbage Bag Heat Bottom Sealing Cold Cutting Non Woven Automatic Shopping Bag Making Machine for Biodegradable PLA

Overview Product Description Pastic bag bottom sealing bag making machine Specification: Detailed Photos Other product r

Overview

Specification:

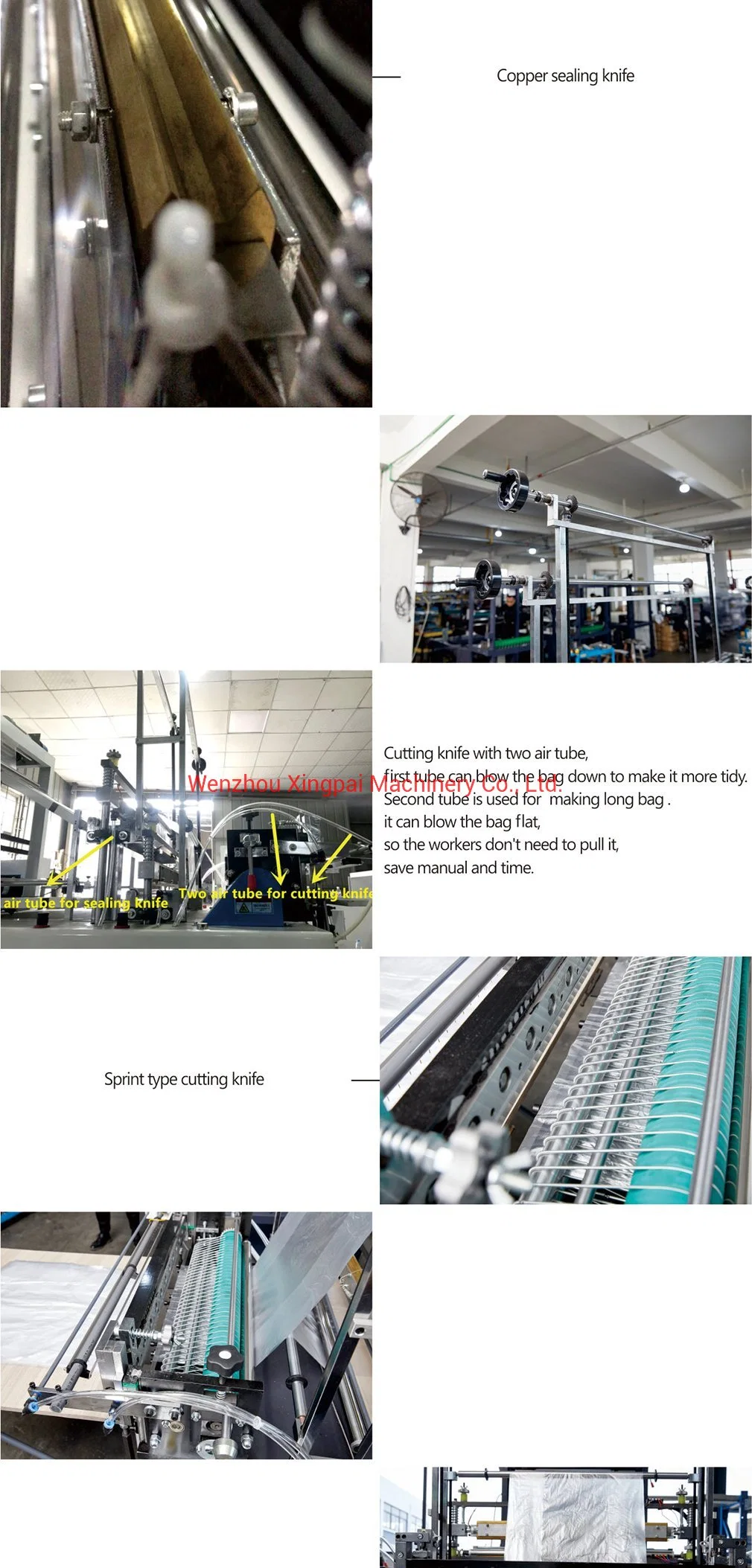

Detailed Photos

workshop pictureGroup picture with customercustomer feedbackPackaging & ShippingFAQ

A: We would express the free replacement parts during the warranty date.9: Does your engineer understand English?

A: Our engineer understand a little English. All our engineer have more than five years machine installation experience. In addition, they can use body language to communicate with customer.

Basic Info.

| Model NO. | XP |

| Continuous-Rolled | No |

| Sealing & Cutting | Heat-Sealing Cold-Cutting |

| Layer | Double |

| Machine Type | Hot Sealing and Cold Cutting |

| Computerized | Computerized |

| Type | Plastic Bag Making Machine |

| Convery Belt | Yes |

| Sealing and Cutting Type | Heat Sealing and Cold Cutting |

| Pneumatic Brake | Yes |

| Inveter | Eura Inverter |

| D Cut Puncher | Optional |

| T-Shirt Puncher | Optional |

| Cutting Knife | Spring Type |

| Control | Computer Control |

| Material | HDPE,LDPE |

| Bags | Polythene Bag ,Nylon Bag ,Shopping Bag . |

| Servo Motor | Chinese Servo Motor |

| Photocell | 1 Pohotocell,Chinese Brand |

| Machine Wall | 10mm |

| Bag | Flat Bag ,Plastic T-Shirt Bag ,Garbage Bag |

| Sealing Knife | Copper,Botttom Sealing |

| Transport Package | Film Package |

| Specification | 600-1500mm |

| Trademark | xingpai |

| Origin | Ruian City, China |

| HS Code | 8477309000 |

| Production Capacity | 10000 |

Product Description

Product DescriptionPastic bag bottom sealing bag making machine

Specification:

| Model | XP-CC 600 | XP-CC 800 | XP-CC 1000 | XP-CC 1200 |

| width of sealing &cutting(mm) | 500*2/250*4 | 700*2 /300*4 | 900*2 /400*4 | 1100*2/500*4 |

| length of sealing & cutting(mm) | 1200 | 1200 | 1500 | 1500 |

| speed of bag-making | 240-480(pcs/min) | |||

| Power of motor(kw) | 1.1 | 1.5 | 1.5 | 1.5 |

| Weight(kg) | 1000 | 1000 | 1200 | 1300 |

| Outline dimension | 3.6*1.3*1.7 | 3.8*1.5*1.7 | 4.2*1.7*1.7 | 4.5*1.9*1.7 |

1.Film blowing machine 2.Bag making machine 3.Printing machine

workshop pictureGroup picture with customercustomer feedbackPackaging & ShippingFAQ

FAQ

1.:Are you factory or trading company ?we are factory specialized in plastic machine for many years ,all of our engineer with more than 20 years experience .2. Where is your factory? How can i visit your company?our factory is located in Ruian city,zhejiang province, China.Its about 40 minutes from shanghai by plane(4 hours by train).we will pick you up on airport or station .welcome to visit our factory3 How long is your delivery time? On normal our delivery time is 30-45 days .if you need it ugently ,we can make your machine first.about 10 days 4.:What's your warranty policy?18 month guarantee and whole life maintance , 5:What package do you use for the product?Be Coated with anti-corrosion oil, and covered with plastic film, wooden box package need extra cost . 6:Does your factory provide installation service?Our engineer can go to customer factory to installation . buyer should prepare materials used to testing the machine in advance and should be responsible for the cost of supplier's technician, including round air tickets, visa cost, accommodation and salary 100USD/Day per person since the day start out until the day arriving at factory.7:What are your terms of payment?We accept T/T, L/C. western union.8. How could we do if the parts broken within warranty?A: We would express the free replacement parts during the warranty date.9: Does your engineer understand English?

A: Our engineer understand a little English. All our engineer have more than five years machine installation experience. In addition, they can use body language to communicate with customer.